What is the recommended method for installing the Rubber torsion axle with mechanical brakeand electric drum brake system onto the trailer frame?

Installing a

rubber torsion axle with mechanical brake and electric drum brake system onto a trailer frame involves several steps to ensure proper fitment, alignment, and functionality. While the specific installation process may vary depending on the manufacturer and design of the components, here is a general outline of the recommended method:

Tools and Materials Needed:

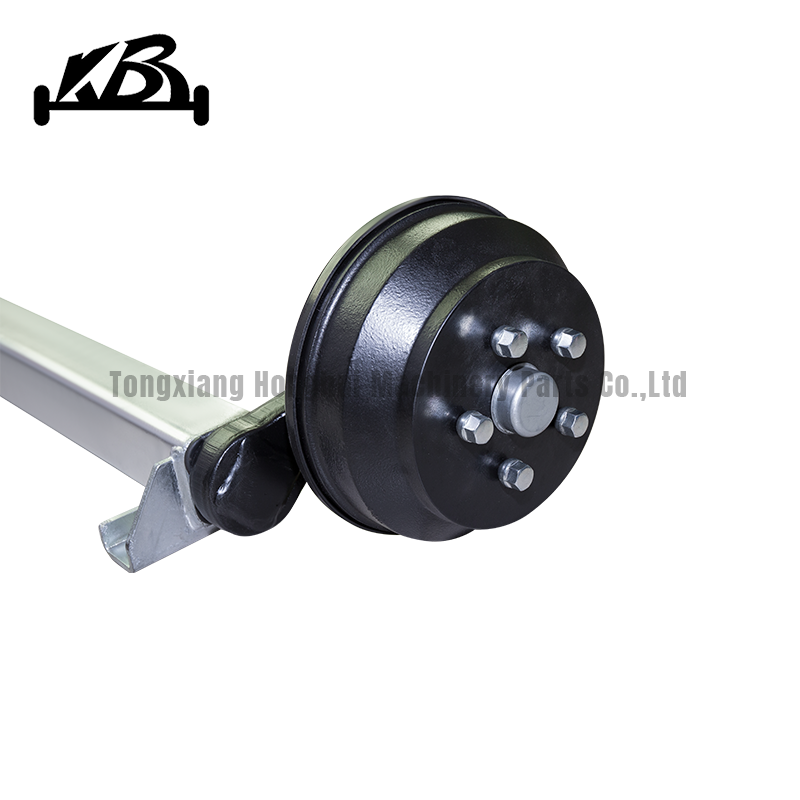

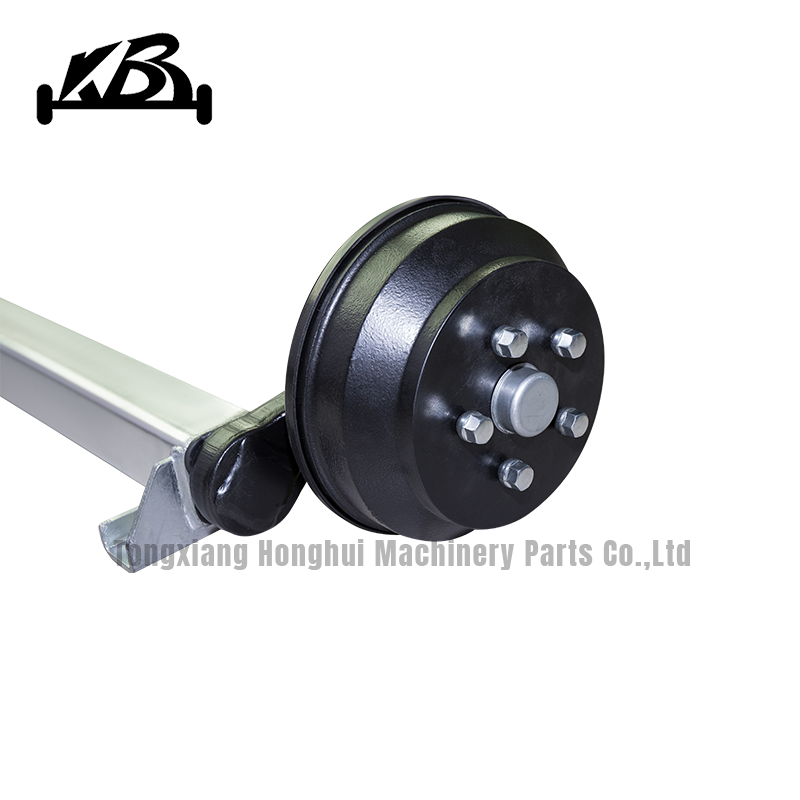

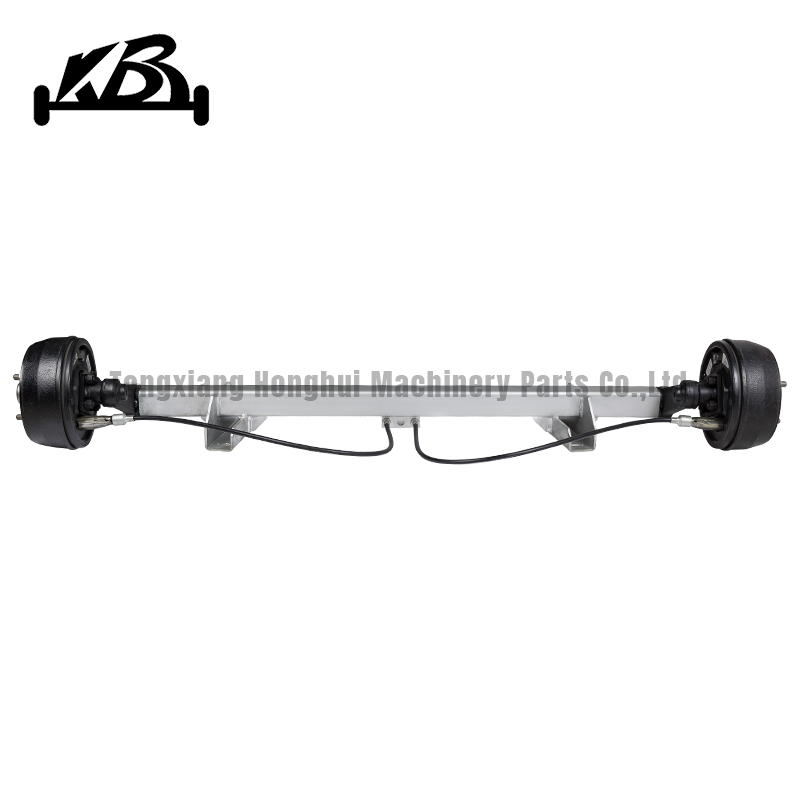

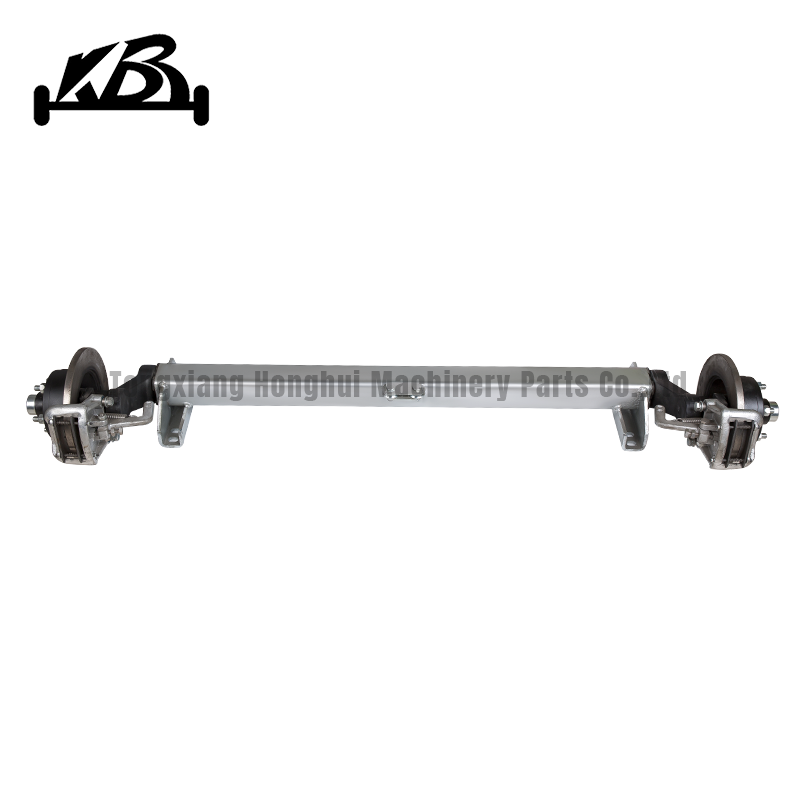

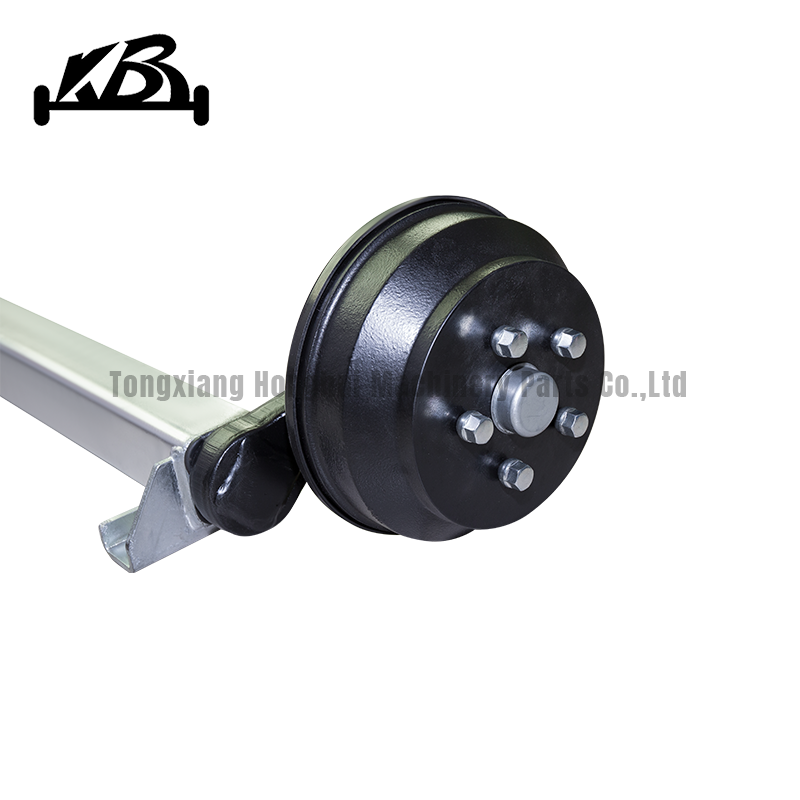

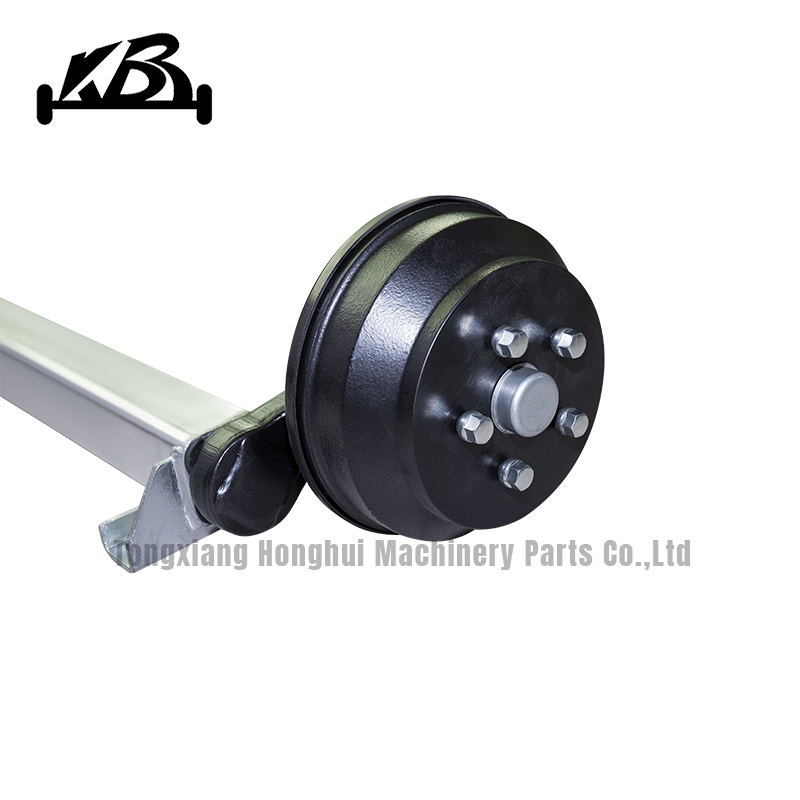

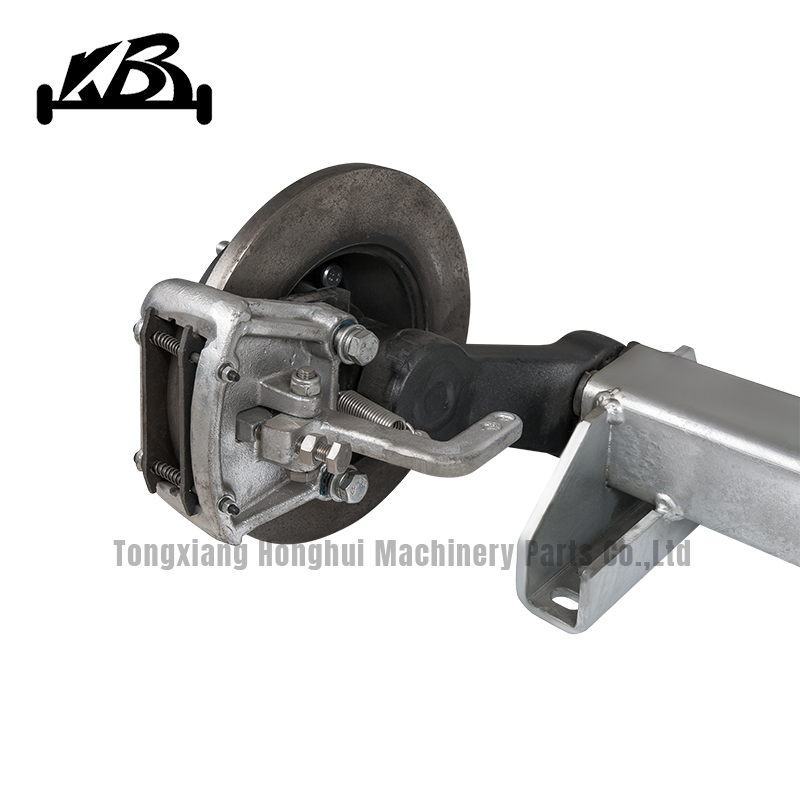

Rubber torsion axle assembly with mechanical brake and electric drum brake components

Trailer frame

Mounting hardware (bolts, nuts, washers)

Torque wrench

Jack stands or hydraulic lift

Safety equipment (gloves, eye protection)

Installation Steps:

Prepare the Trailer:

a. Park the trailer on a level surface and engage the parking brake.

b. Use jack stands or a hydraulic lift to raise the trailer frame, ensuring it is stable and secure.

Assemble Brake Components:

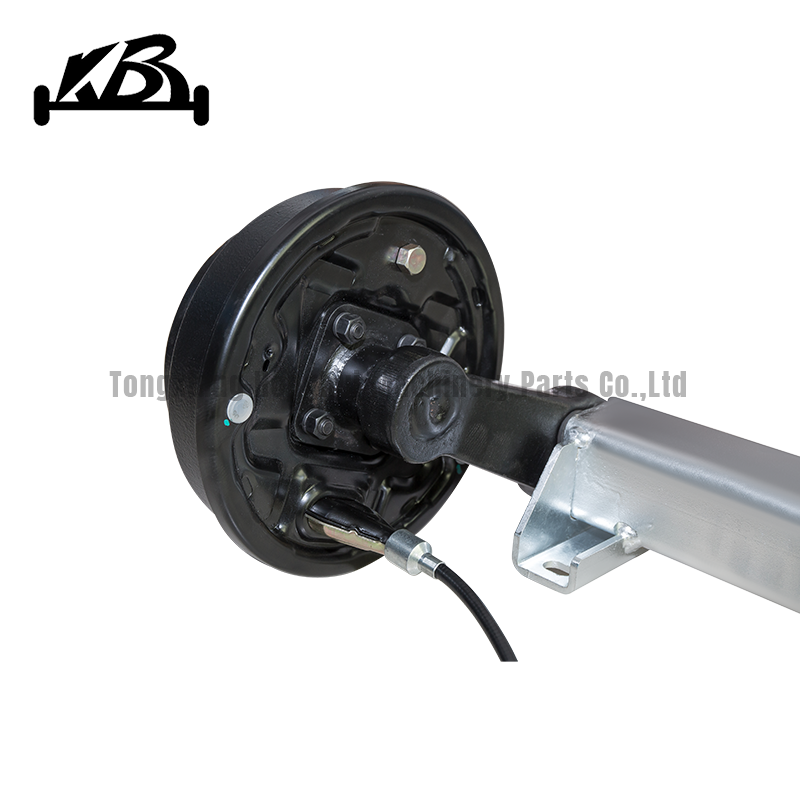

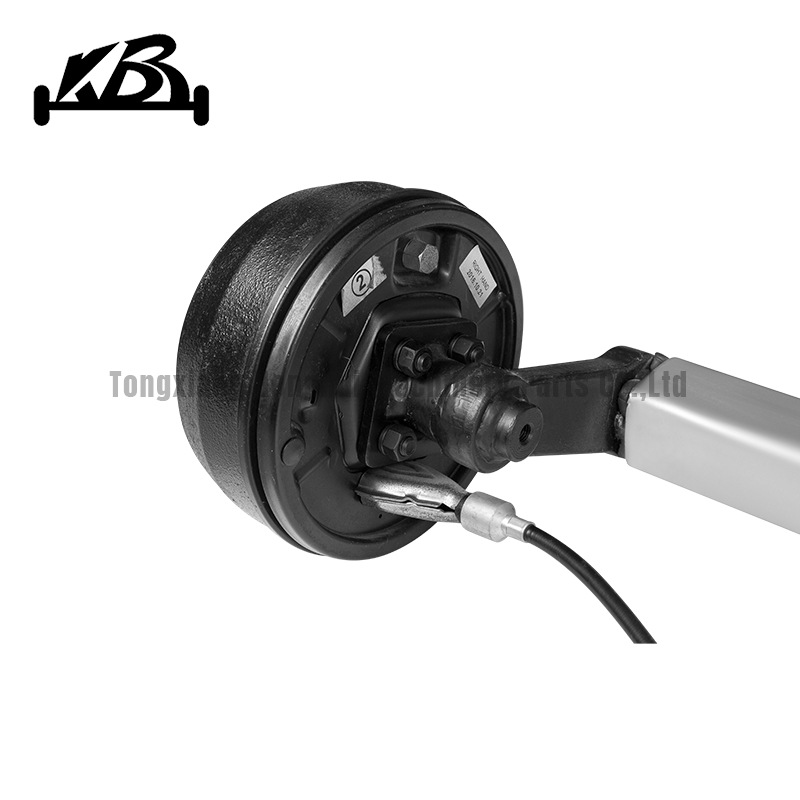

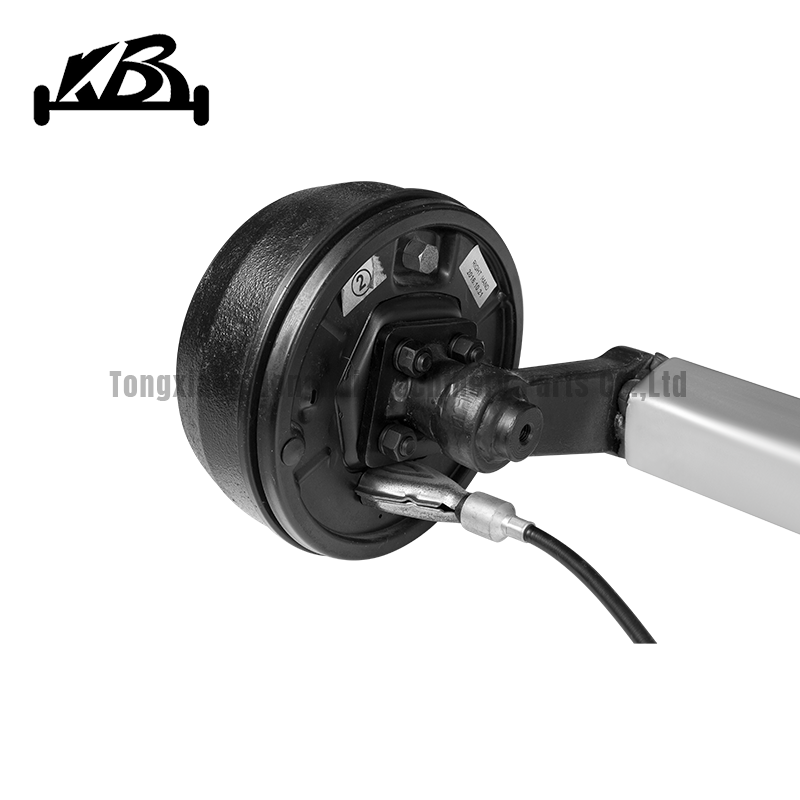

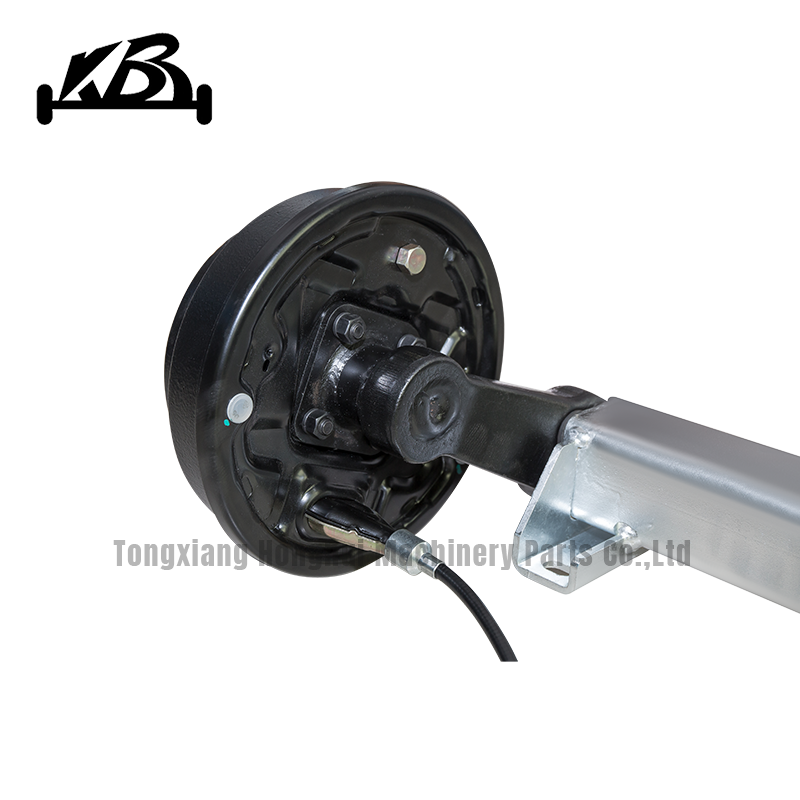

a. Install the electric drum brake assemblies onto the axle spindles according to the manufacturer's instructions. This typically involves attaching the brake backing plate to the axle flange and securing it with nuts and bolts.

b. Connect the brake wires to the appropriate connectors, following the wiring diagram provided by the manufacturer.

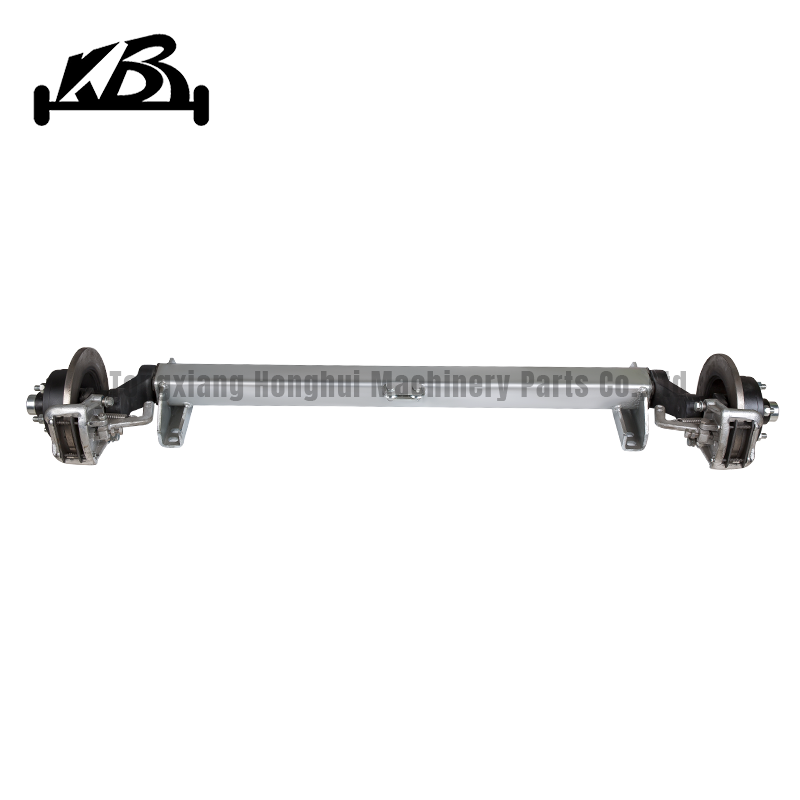

Position the Axle:

a. Carefully align the rubber torsion axle under the trailer frame, ensuring that it is centered and square with the frame.

b. Use temporary supports to hold the axle in place while you secure it to the frame.

Attach Axle to Frame:

a. Insert the axle mounting brackets onto the trailer frame, ensuring they are positioned according to the axle manufacturer's recommendations.

b. Insert bolts through the axle brackets and frame mounting points.

c. Secure the bolts with washers and nuts, but do not fully tighten them at this stage.

Check Alignment and Leveling:

a. Use a level to ensure that the axle is aligned horizontally and parallel to the ground.

b. Adjust the axle position and mounting brackets if necessary to achieve proper alignment.

Torque Bolts:

a. Starting from the center and working outward, torque the axle mounting bolts to the specifications provided by the axle manufacturer. Use a torque wrench to ensure accurate torque values.

Connect Brake Wiring:

a. Route the brake wires along the trailer frame and secure them using clips or cable ties.

b. Connect the brake wires to the trailer's electrical system, following the manufacturer's wiring diagram.

Adjust Brakes:

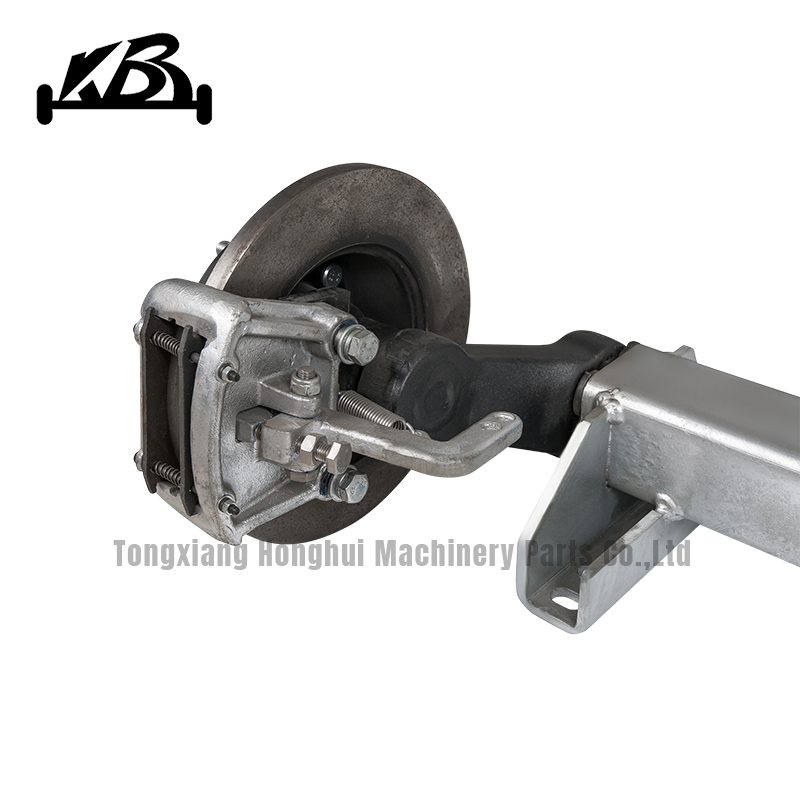

a. Follow the brake adjustment procedure provided by the brake manufacturer to properly adjust the mechanical brakes.

b. Ensure that the brake shoes make proper contact with the drum and that the brakes engage smoothly.

Test the System:

a. Lower the trailer onto its wheels and remove the supports.

b. Test the brake system by towing the trailer in a safe area. Ensure that the brakes engage and release properly and that the trailer stops smoothly.

Final Check:

a. Double-check all bolts, nuts, and connections to ensure they are properly tightened and secure.

b. Inspect the entire installation for any signs of misalignment, interference, or safety issues.

Are there any specific design considerations for compatibility between the Rubber torsion axle with mechanical brake and the electric drum brake components?

Yes, there are specific design considerations and compatibility factors that need to be taken into account when combining a

rubber torsion axle with mechanical brakes and electric drum brake components. Ensuring proper compatibility is crucial to the safe and effective operation of the trailer's suspension and braking systems. Here are some key considerations:

Axle and Brake Component Sizing:

The mechanical brakes and electric drum brake components should be appropriately sized to match the load capacity and weight rating of the rubber torsion axle. Ensure that the brake assemblies are compatible with the axle's spindle and flange dimensions.

Brake Mounting Compatibility:

Verify that the brake backing plates and components can be securely and properly mounted onto the rubber torsion axle without interfering with its operation or compromising its integrity.

Wiring Integration:

The electric drum brake system requires wiring connections to the trailer's electrical system. Ensure that the wiring harness and connectors can be easily integrated into the trailer's setup, and that there is proper routing and protection to prevent damage or wear.

Brake Controller Compatibility:

The electric drum brakes require a brake controller in the towing vehicle to activate the trailer brakes. Ensure that the brake controller is compatible with the electric brake system and that it is set up and calibrated correctly.

Suspension Geometry:

Verify that the installation of the mechanical brakes and electric drum brake components does not alter the suspension geometry or affect the operation of the rubber torsion axle. The suspension should still provide the intended suspension and ride characteristics.

Wheel and Tire Clearance:

Check for adequate clearance between the brake components, wheels, and tires. Make sure that the brake drums, brake shoes, and other parts do not interfere with the rotation of the wheels or cause rubbing against the tires.

Manufacturer Recommendations:

Follow the manufacturer's guidelines, instructions, and specifications for installing both the rubber torsion axle and the brake components. Manufacturers often provide specific recommendations for compatibility and installation.

Regulatory Compliance:

Ensure that the combined rubber torsion axle with mechanical and electric brakes complies with relevant safety standards and regulations in your jurisdiction.

Professional Expertise:

中文简体

中文简体